Panels for Isocanale system

AQS is now a provider of Stiferite panels, the specialist panelling used in the fabrication of pre-insulated ventilation ducts.

A wide range of panels are available with the following variables:

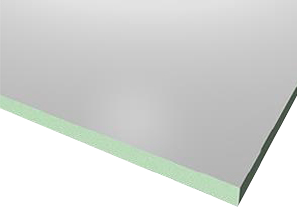

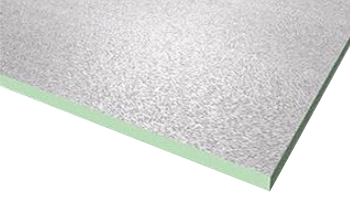

- The thickness of the aluminium facer

- Finish surface of the facer: smooth or embossed

- The density of the Polyiso foam

- The thickness of the panel, 20 or 30 mm

|

|

|

All panels are the standard dimensions of 1200 x 4000 mm and made using Polyiso foam with an initial thermal conductivity (λi) of 0,021 W/mK. Panels are available on request in a combination of facer thicknesses.

| Smooth aluminium finish |

|

|

| Embossed aluminium finish |

|

|

ISOCANALE Indoor

There are 3 types of ISOCANALE Indoor for internal use in residential, commercial or industrial buildings.

ALC is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocynurate PIR foam. Both sides of the panel are covered with 80 μm embossed aluminium foil.

Foam density: 45 ± 3.0 kg/m3

A16 is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocynurate PIR foam. Both sides of the panel are covered with 60 μm embossed aluminium foil.

Foam density: 35 ± 3.0 kg/m3

A18 is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocyanurate PIR foam. It’s covered on both sides with an 80 μm embossed aluminium foil.

Density of the foam: 35 ± 3.0 kg/m3

For external use in residential/commercial and industrial buildings

ISOCANALE Outdoor

STIFERITE ALE is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocyanurate PIR foam. One side of the panel is covered with an 80 μm embossed aluminium foil and the other side is 200 μm embossed aluminium foil.

Foam density: 45 ± 3.0 kg/m3

A12 is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocyanurate PIR foam. One side of the panel is covered with an 80 μm embossed aluminium foil and the other side is 200 μm embossed aluminium foil.

Foam density: 35 ± 3. 0 kg/m3

ISOCANALE Extreme

This panel is recommended for applications in ‘aggressive environments’ such as swimming pools and saltwater areas.

LBV3 is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocyanurate PIR foam. Both sides of the panel are covered with an 80 μm embossed aluminium foil treated with white corrosion proof lacquer.

Foam density: 35 ± 3.0 kg/m3

ISOCANALE Clean

This panel is recommended for applications of very clean environments such as hospitals, laboratories and clean rooms.

AAB Is a high-performance insulation board manufactured from CFC or HCFC free closed cell rigid polyisocyanurate PIR foam. One side of the panel is covered with an 80 μm embossed aluminium foil and on the other side with an 80 μm smooth aluminium foil lacquered by an antimicrobic material.

Foam density: 45 ± 3.0 kg/m3

|

| Versatile simple economical clean lightweight silence |

|

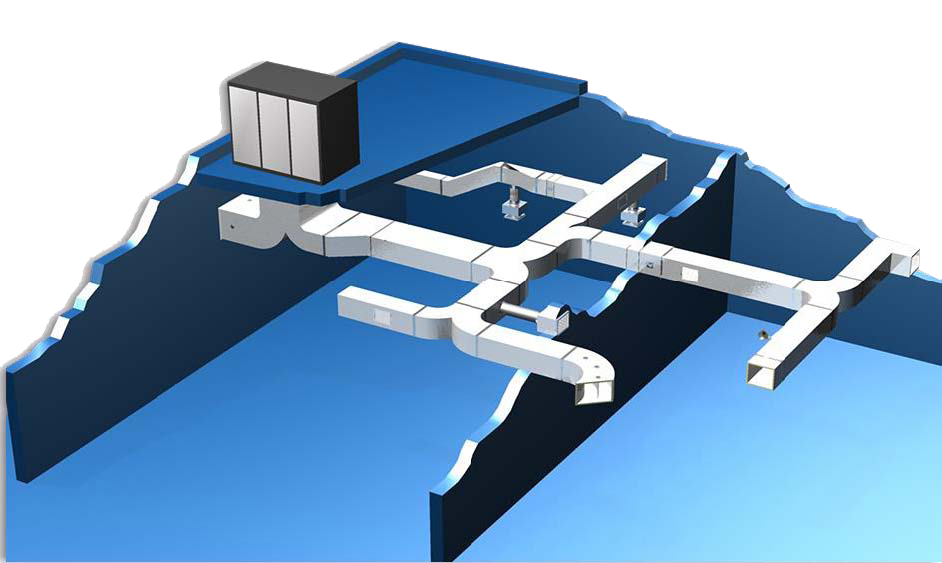

Advantages of the ISOCANALE system

A highly efficient system and excellent air quality

The internal surface of the ISOCANALE duct is constructed entirely out of aluminium, which guarantees a flow of clean air.

The limited flanges used in the ISOCANALE system that join individual duct sections together provide a pneumatic hold that additionally enhances the efficiency of the system.

Energy efficient and thermal insulation

Stiferite’s Polyurethane foam has a very low thermal conductivity coefficient of λi = 0,021 W/m guaranteeing near-perfect thermal insulation even at reduced thicknesses such as 20 and 30mm.

This feature significantly limits the energy consumption of the entire ventilation system and the aluminium facers present on both sides of the panel result in excellent waterproofing and vapour- blocking performance.

Lightweight and safe

Pre-insulated ducts are nearly 15% of the weight of traditional sheet metal ducts. This gives the ducting a genuine and competitive edge in terms of economy, environment and safety.

Lighter ducts require less anchoring points and are much safer in the unlikely event of a fall due to an accident or earthquake.

Another safety advantage is the excellent end-use condition fire rating of Euroclass B s1 d0.

Minimum Noise

Stiferite’s polyurethane foam panels have qualities that reduce vibration and absorb noise. This can have a big impact on quality of the environment where the ducting is installed.

Durability

The use of polyurethane foam and aluminium, guarantee a system that will endure for many years once installed.

Reduced Costs

Compared to traditional sheet metal ducts, the cost of a pre-insulated duct system is significantly lower in terms of manufacture, shipping and on-site installation.

Versatility

The panels that make up the system, can be cut to size directly on-site. This means that complex air distribution routes can be easily installed and adjusted to take into account revised needs across the system without any difficulty.

You can cut the duct panels either width or length direction taking into account the duct’s dimensions and the material used.

It is possible to optimise the duct’s mechanical characteristics and fully utilise the panelling, resulting in minimal waste.

Diifferent cutting methods may be employed, each with its own limiting dimension. Here are 3 examples of the recommended cutting and installation methods, you can find other methods in the Fabrication Guide.